News

Mitsubishi Electric Develops Physics-Embedded AI for Accurate Estimation of Equipment Degradation from Small Amounts of Training Data

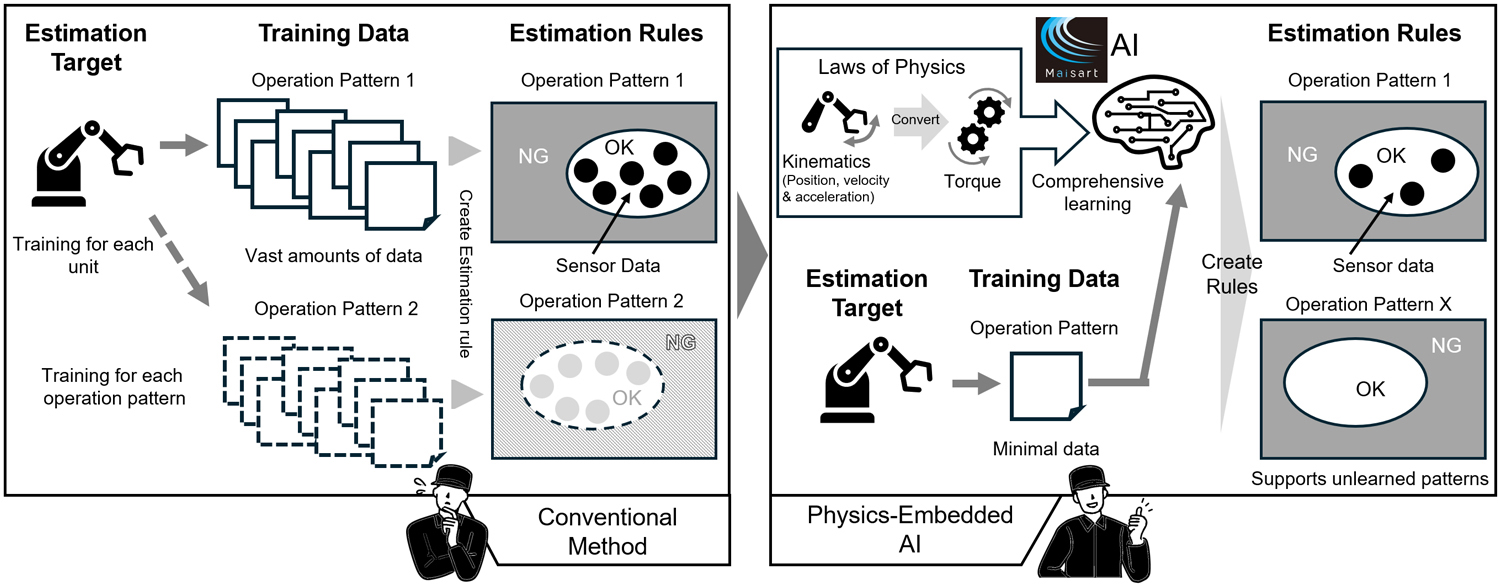

Advantages of physics-embedded AI vs. conventional degradation estimation

TOKYO, December 10, 2025 - Mitsubishi Electric Corporation(TOKYO: 6503) announced today that it has developed a physics-embedded AI1 that can accurately estimate equipment degradation using minimal training data. The technology is an outcome of the company's Neuro-Physical AI2 initiative within its Maisart®3 AI program, which emphasizes reliability and safety in the physical world. Leveraging Mitsubishi Electric's extensive equipment-development expertise, the new technology supports the optimization of manufacturing-site assets to maintain productivity and quality as well as reduce maintenance costs.

Japan's manufacturing sector is deploying increasingly sophisticated production equipment at a time when the nation's aging and shrinking population is reducing the number of experienced maintenance technicians. Meanwhile, there is a growing demand for preventive-maintenance solutions that can predict equipment degradation for timely responses, since continued use of degraded equipment can result in equipment failure or defective products. Conventional preventive maintenance typically mimics equipment behavior using mathematical models or simulations to estimate degradation. But this approach requires domain experts with knowledge of physical systems to design degradation-detection mechanisms from scratch, which can require significant time and effort. To address this issue, there is a movement to estimate degradation by training AI with operational data. However, these efforts typically require vast amounts of data to comprehensively cover diverse operating patterns, unit-to-unit variability and installation environments, as well as retraining whenever conditions change, hindering the practical deployment of AI to estimate equipment degradation.

In response, Mitsubishi Electric's Information Technology R&D Center in Kamakura, Kanagawa Prefecture, Japan and Mitsubishi Electric Research Laboratories, Inc. in Cambridge, Massachusetts, USA have developed an AI that is pre-trained using the theoretical equations of a device's physical model, enabling the AI to learn the device's expected behavior and characteristics in advance. Then, by providing a small amount of measured data reflecting unit-to-unit variability and environmental conditions, the AI can accurately estimate degradation. When embedding a physical model into AI, previous approaches fixed the weighting4 between the model and measured data, making optimization for different devices or environments difficult. However, the new technology enables the AI to dynamically adjust these parameters, resulting in higher estimation accuracy and improved usability.

Consequently, this new technology can prevent major equipment failures and reduce the need for part replacements at manufacturing facilities, thereby helping to lower maintenance costs while maintaining productivity and product quality.

- 1

An approach that bases AI systems on a physical model—an analytical mechanism that reproduces a machine's behavior and characteristics using physical laws and equations—and embeds that knowledge and theory into AI to achieve more accurate and physically consistent prediction and control.

- 2

Mitsubishi Electric's proprietary physical AI integrates decades of business expertise, on-site know-how and insights with physical laws, making equipment and entire systems smarter, safer and more reliable.

- 3

"Mitsubishi Electric’s AI creates the State-of-the-ART in technology" :

Mitsubishi Electric’s AI technology brand aimed at making every device smarter.

- 4

Weighting between physical model and measured data: A numerical weight representing how much importance to place on each information source when combining a physical model with measured data.

Inquiry

-

Customer Inquiries

Information Technology R&D Center

Mitsubishi Electric Corporation

Search by category or year of publication

There are no articles for the condition you specified.