FOR IMMEDIATE RELEASE No. 3148

Mitsubishi Electric Introduces New Edge-computing Software and Products

Advanced processing of production-floor data contributes to preventative maintenance and product quality

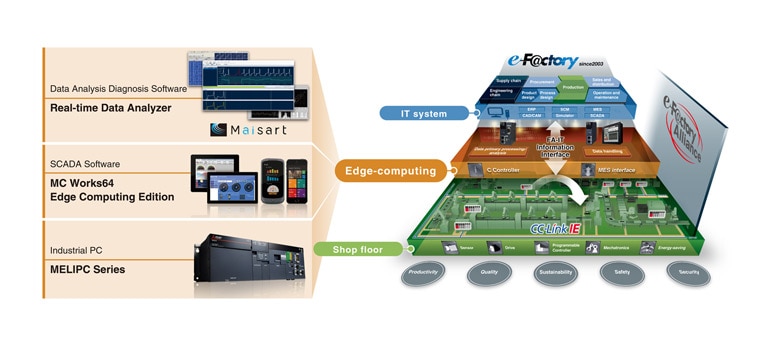

TOKYO, November 7, 2017 - Mitsubishi Electric Corporation (TOKYO: 6503) announced today that it has developed supervisory control and data acquisition (SCADA) software and industrial-use computers that it will incorporate in e-F@ctory-brand solutions for edge computing on production floors where network edges and data sources intersect. The new offerings will greatly enhance smart-manufacturing processes for production data collection and analysis as well as real-time diagnostics to strengthen preventive maintenance and product quality. Solutions will support the Edgecross open-software platform facilitating connectivity between production floors and value chains via the Internet of Things (IoT) systems. A commercial launch is expected in the spring of 2018.

Mitsubishi Electric will exhibit its new edge-computing software and products at the System Control Fair at the Tokyo Big Sight exhibition complex from November 28 to December 1 and the China International Industry Fair at the National Exhibition and Convention Center in Shanghai from November 7 to 11.

Key Features

- 1)

- Real-time Data Analyzer (data analysis and diagnostics software)

- Create diagnostics rules by conducting offline analysis of shop data and then executing real-time diagnostics of production systems during operation.

- Improve the accuracy of detecting equipment anomalies during real-time diagnostics using Maisart-brand waveform recognition technology to learn and recognize data, such as sensor waveform patterns.

(Maisart: "Mitsubishi Electric's AI creates the State-of-the-ART in technology").

- Implement preventive maintenance and quality improvement using statistical diagnostic tools, such as the Mahalanobis-Taguchi method and multivariable regression analysis for data analysis. - 2)

-

MC Works64 Edge-computing Edition (SCADA software)

- Easily monitor data across the entire production floor with special sensors and devices.

- Use best-in-class visualization, including 3D graphics, and remote monitoring (via Web browser and mobile devices) to access KPI data anytime, anywhere.

- Easy to use and simple configuration dedicated to edge-computing applications. - 3)

-

MELIPC Series (industrial-use computers)

- Rugged, high-reliability design based on MELSEC Series PLC quality standards.

- Meets diverse needs, ranging from high-end models offering high-performance processors and built-in CC-LINK IE for high-speed communications to lower-end small-profile models suited to simple tasks.

- Will be expanded with lines offering new functions, such as drive and motion control.

Note that the releases are accurate at the time of publication but may be subject to change without notice.